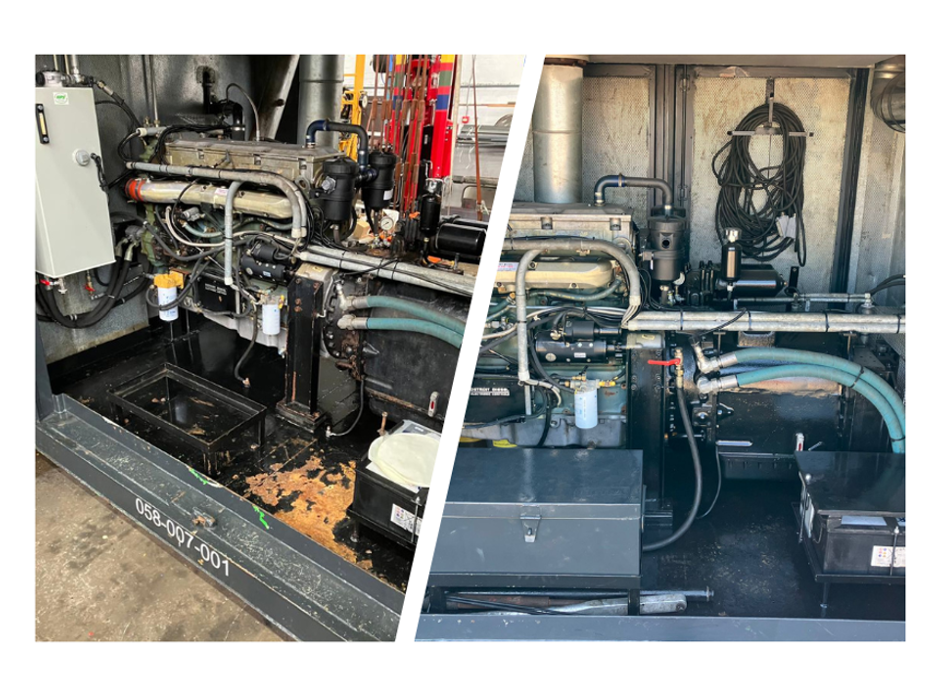

Mud pump container like new again!

What was your latest project?

'We recently completed a project for major overhaul of a mud pump container. A mud pump is used to pump fluids while drilling new wells, repairing existing wells or plugging existing wells. A mud pump is able to pump large volumes and is capable of doing so under high pressure,' David explains.

What did the project involve?

'We carried out the full scope of maintenance on all parts of the mud pump container: the mud pump itself, the propulsion motor, the gearbox and the container in which these parts are mounted. This involved a wide range of activities: hydraulic, mechanical and electrical. All in all, the lead time was just under seven weeks and the project surely included some challenges.'

Which challenges that were?

David continues: 'First of all, the delivery times and component costs: both are rising significantly due to the present tightness in the market. An extra challenge was that the engine's serial number was unidentified by the manufacturer. So, just try to find the exact right spare part, which can also be delivered on time!'

'This sometimes requires you to be inventive and make other choices that do fit within the delivery deadline and budget. In close consultation with the customer, of course, and while maintaining the quality and reliability of the machine. I admit: that took me quite some time and headaches'.

Has any work been outsourced?

'We performed almost everything in-house,' says David. 'Only for the forklift pockets component have we made a different choice: again, we could have done this ourselves, but in our engineering department we had insufficient capacity at present for this project element. We decided to therefore completely outsource the forklift pockets scope, from engineering to installation. I also supervised this scope and maintained close contact with our contractor to monitor quality and progress and to carry out visual inspections.'

'By the way, these forklift pockets are a very handy feature for this type of mud pump container,' David notes. 'This is because the container was originally only equipped with hoisting facilities for hooking slings. This means that a crane is required at all times to pick up and load the container. Using forklift pockets, the container can safely be picked up and moved with a forklift truck. However, by fitting these pockets, you do change the construction of the container. Therefore, a structural engineer has to be involved to calculate its placement.'

Why do clients choose Wagenborg Foxdrill to perform such an overhaul?

David doesn't have to think long about that: 'If you entrust such a project to us, you are opting for a maintenance partner that guarantees quality in execution and has an incredibly broad in-house service package. Moreover, at Wagenborg Foxdrill we have the right knowledge of applicable legislation and standards. And we have a big network of high-quality partners. This approach enables us to achieve every goal!'