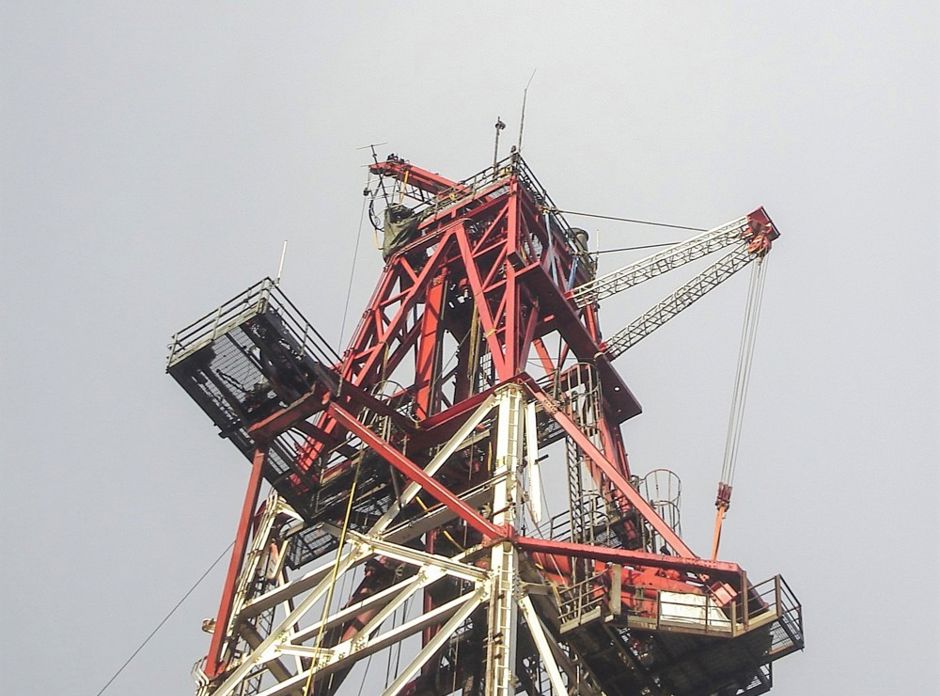

Wagenborg Foxdrill - Your Derrick Specialists

For derrick construction, modifications, inspections, repairs, and decommissioning, Wagenborg Foxdrill’s derrick specialists have you covered.

![Afbeelding 213[1]](/media/lppjrwsk/afbeelding-213-1.jpg?width=1800&height=950&v=1dbf0f7f2145a10)

Reduce your project costs and risks

Wagenborg Foxdrill provides professional Derrick Services from derrick construction to decommissioning and all steps in between. Our 50+ years of experience means we’ve seen it all and can advise on how to minimize risk and total project costs. Our clients choose us for our get-it done mentality, professional approach, expertise, minimal reliance on contractors, and flexibility.

Derrick Modifications

Typical modification projects executed by Wagenborg Foxdrill include the removal and reinstallation of crown block and/or crown-mounted compensator cylinders, the installation of derrick extensions, derrick beef-ups, replacement and alignment of guide rails, pipe handling and drilling systems, bolt replacements, or the installation of wind walls, heat shield, winterization and vent lines. We have also completed full derrick removals for ship conversions for the heavy lift industry and for deep sea mining.

For the execution of repair and modification projects we have a variety of equipment to choose from, such as ultra-light rigging, floating gin pole, winches, and netting systems. For complex projects we are able to engineer new solutions, and train our people with the proposed solutions on our in-house test mast and training facility.

- custom lifting equipment

- decades of experience

- in-house testing and training facility

Inspections

Wagenborg Foxdrill offers complete derrick inspections, including API, Bolt tightness, & Dropped Object (DROPS) inspections, for all types of rigs and equipment - onshore and offshore.

Our derrick inspections are performed in accordance with detailed checklists and clear criteria, based on API requirements. We are always aiming to provide our clients with the best and most useful information possible.

To put our client’s interest first, we often provide custom derrick inspection scopes. If you don’t need a full API 4G inspections but just a look at guide tracks or primary steel? Then we are glad to help you out.

Before we leave your installation we always provide preliminary information including high-risk items. This way safety incidents or non-productive time can be avoided.

- API CAT III /IV, DROPS, and other inspections for derricks and entire rigs

- high experienced personnel

- done right the first time

Equipment Solutions

Contact Wagenborg Foxdrill to replace, exchange or maintain equipment in your derrick. Our equipment solutions include:

- crown blocks

- travelling blocks

- top drive change-out

- pipe handling systems

- racking systems

- fingerboards

- installation / replacement of crown mounted compensator cylinders (CMC's)

- heat shielding / wind walls

Our equipment solutions also include inspections and repairs for all types of drilling equipment and lifting equipment under the hook.

Our custom hoisting solutions enable us to handle all items in the derrick.

Custom Rigging & Lifting Solutions

Wagenborg Foxdrill can access where others can’t.

Using our in-house engineering and decades of rigging experience, we provide custom lifting solutions to work beyond the reach of cranes. Examples include our Lightweight Lifting System, and our floating gin pole for crane-less removal of derrick structures.

We also provide solutions for various industries including civil construction, oil & gas / drilling & facilities, offshore wind, & telecoms.

- in-house engineering solutions

- reach where cranes can't

- hoisting & access solutions for equipment and personnel

Derrick Building

Wagenborg Foxdrill have been building derricks for over 50 years, all over the globe. Our Derrick Assembly services include construction and trial fitting of land rigs and offshore derricks worldwide.

Wagenborg Foxdrill has experience with a variety of rig and derrick types, such as static, dynamic, single and dual derricks. Proven techniques, thorough preparation, and careful planning ensure that the project is done correctly the first time.

To support a safe and efficient operation we provide project specific lifting equipment. Our consulting services have contributed to the improved design of derricks to ensure simpler assembly and construction.

- decades of experience

- assembly & modification of all types of derricks

- in-house engineering & knowledgeable personnel