Mixtank overhaul

Wagenborg Foxdrill's maintenance team recently completed the total overhaul of a mixtank. This tank has been used extensively in onshore well testing operations for more than three years. So it was high time for a major overhaul by the Foxdrill specialists.

Intensive use

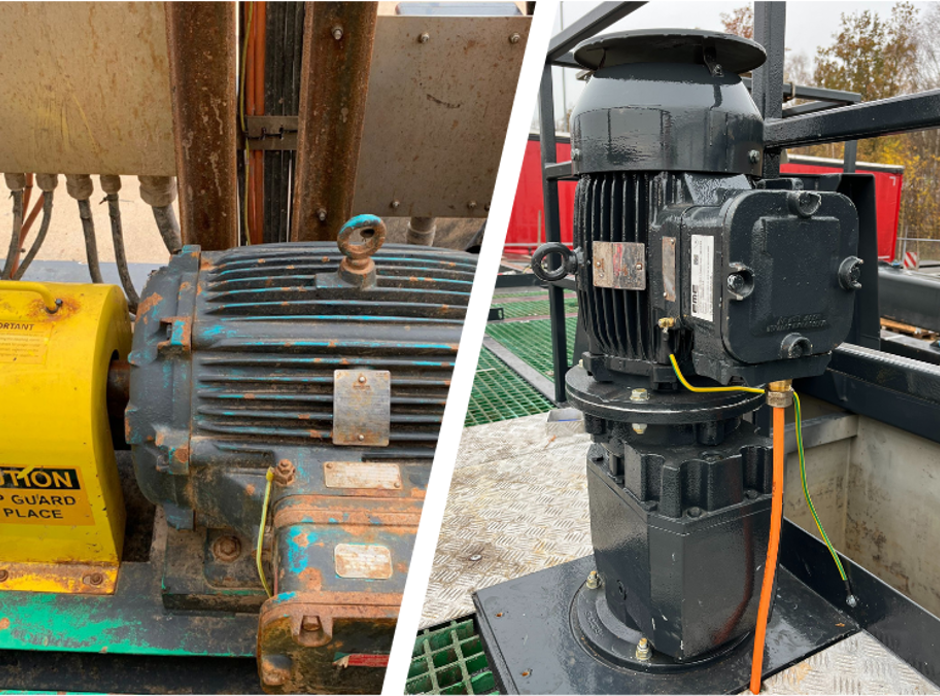

'Due to intensive use, the pumps were worn out, the valves no longer closed properly and there were various other defects,' says Evert Huizing, workshop manager at Wagenborg Foxdrill.

'We therefore carried out a detailed inspection first. This showed which parts could be overhauled and which had to be completely replaced. So we installed new pumps, reduction gears and butterfly valves.'

Teamwork with partners

'The ATEX electric motors were inspected, overhauled and certified by one of our partners. This is a very specific area of expertise in which they excel. We are therefore happy to use their knowledge and expertise in this particular field.

With our own commitment, knowledge and experience, together with that of our partners, we achieve the best possible result for the customer.'

In-house inspection

'Wall thickness measurements were also carried out on all the pipework, and the tank was blasted and repainted. We then rebuilt the mixing tank with the new and reconditioned parts.

Finally, the entire unit was inspected and certified to NEN-EN-IEC 60079-17 by our in-house inspector.'

All in all, another great overhaul project with a satisfied customer as a result!