Inventive solution on knuckle boom crane cylinders prevents drillship downtime

Preventing downtime

Quite a challenge, as these cylinders weigh almost 14 tonnes each and replacing them would require the drillship to go into port. This is costly, and drilling operations would also have to be interrupted.

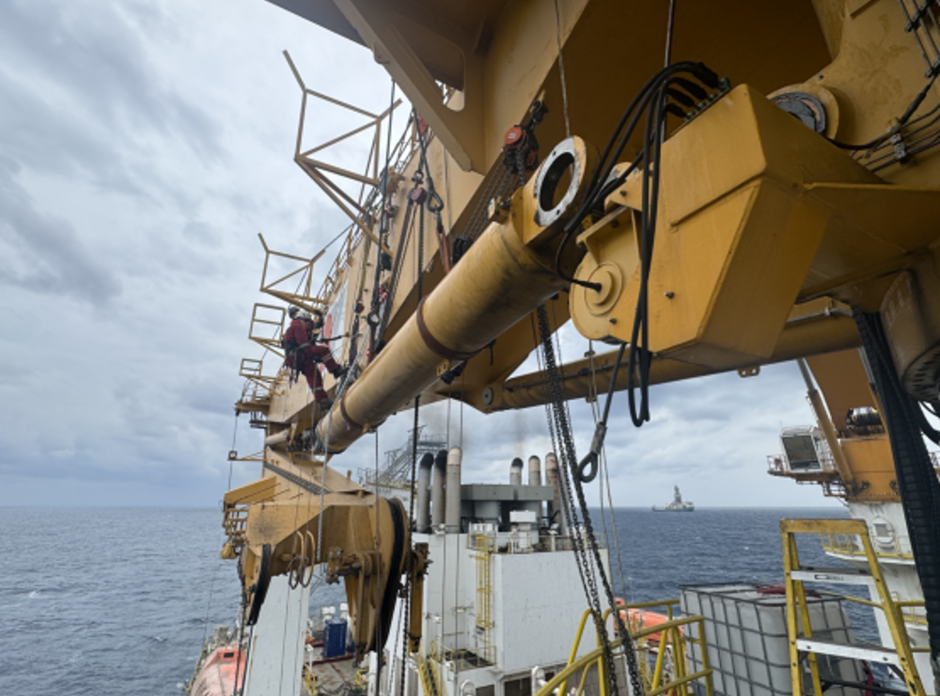

Wagenborg Foxdrill came up with an ingenious offshore rope access solution. This involved dismantling the main boom cylinders of the knuckle boom crane while the drillship remained in operation.

Inventive lifting solution

This was an extraordinary job, because with a length of 7.5 metres and a weight of almost 14 tonnes, these cylinders are not easy to handle. Foxdrill's team of engineers and rope access specialists developed a safe lifting solution. This involved using the upper arm of each knuckle boom crane. To this, the rope access team attached the necessary rigging, consisting of an ingenious combination of chain hoists.

After disconnecting the hydraulic hoses and removing the fixing pins, the rope access team carefully lowered the cylinder several meters to a position where it could be picked up by one of the other knuckle boom cranes.

To install the new cylinders, the lifting operation was carried out in reverse order.

Saving time and money

This inventive offshore approach by the Foxdrill team allowed the planned drilling operations to continue uninterrupted, eliminating downtime. In addition, port visits were avoided, resulting in significant time and cost savings.